The Hidden Cost of Galling in the Oilfield

Why Ignoring Thread Protection Leads to Bigger Losses Than You Think

In the high-pressure, high-stakes world of oil and gas, every connection matters. OCTG (Oil Country Tubular Goods) accessories like couplings, crossovers, pup joints, and tool joints are designed to withstand extreme downhole conditions. Yet one of the most overlooked threats to operational efficiency and equipment longevity is something seemingly small: thread galling.

At Sterling Impreglon Asia, we see first-hand how the hidden costs of galling can snowball into major financial and operational setbacks for drilling contractors, service companies, and asset owners.

🔍 What is Galling and Why Does It Happen?

Galling occurs when metal threads under pressure adhere to each other, tearing material away during make-up or break-out. It is caused by:

- High torque and friction without sufficient lubrication

- Steel-on-steel contact without proper surface protection

- Repeated make-and-break cycles under harsh conditions

Both premium and non-premium connections are vulnerable—especially when protective measures like Brush Copper Plating are overlooked.

💸 The Real, Often Overlooked Costs of Galling

🔹

Damaged Threads = Scrapped Tools

Once threads are galled, repairing them becomes difficult, if not impossible. Many premium connections must be

scrapped entirely—an expensive waste of investment.

🔹

Lost Operational Time

Thread galling delays rig operations. Each hour of downtime offshore or onshore can cost

tens of thousands of dollars.

🔹

Compromised Well Integrity

Galled connections can fail under pressure, risking

seal failures, blowouts, or costly fishing operations.

🔹

Requalification & Replacement Costs

Damaged accessories must often be requalified—or replaced—at high expense, adding further strain to project budgets.

🔹

Reputation and Contract Risks

Repeated galling incidents can lead to

contract penalties, loss of trust with operators, and fewer awarded projects.

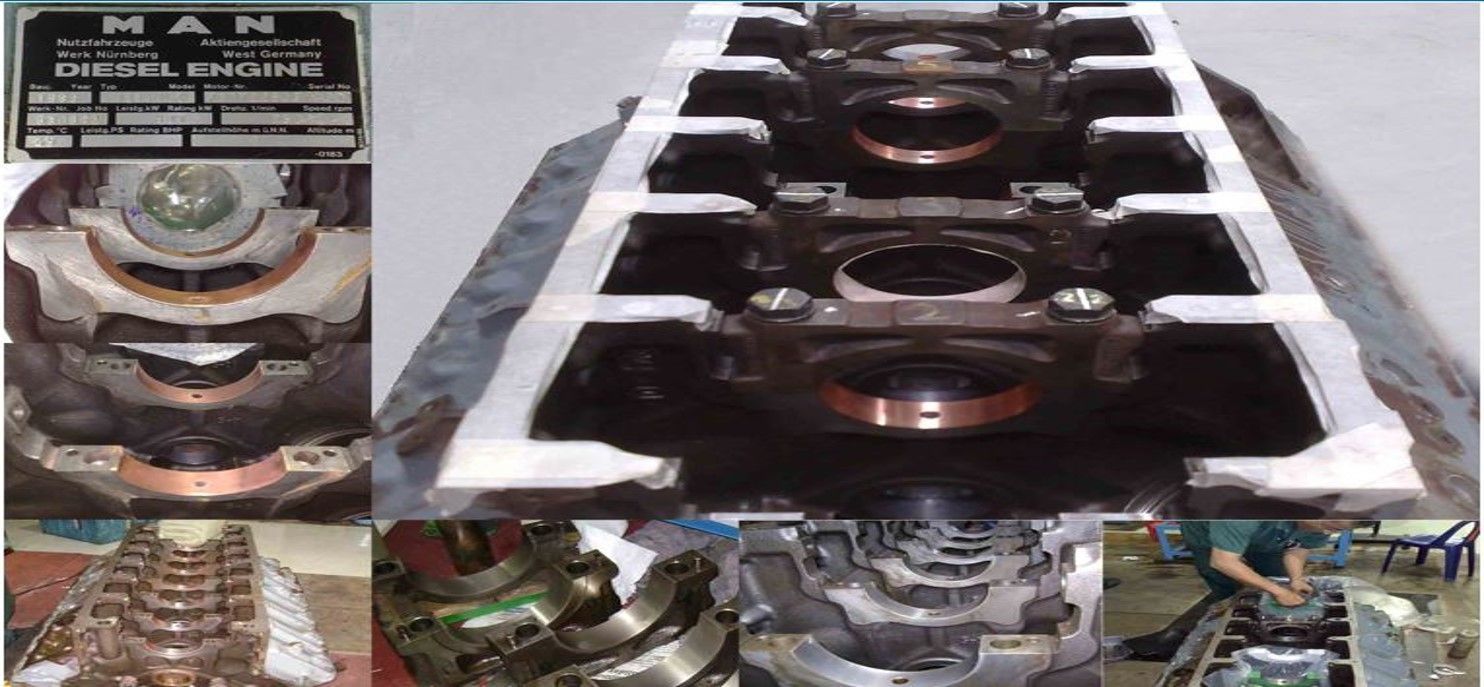

🛠 How Brush Copper Plating Solves the Problem

At Sterling Impreglon Asia, our Brush Copper Plating technology offers a field-proven solution:

✅

Reduces Friction & Prevents Adhesive Wear – Copper acts as a sacrificial, lubricating layer between threads.

✅

Preserves Connection Integrity – Enables safe, smooth make-and-break cycles even under extreme torque.

✅

Extends Tool Life – Premium and non-premium accessories last longer, requiring fewer replacements.

✅

Minimizes Downtime & Unexpected Costs – Keeps drilling operations on track, saving money and avoiding unnecessary delays.

💬 Don't Let Galling Erode Your Profit

The cost of ignoring thread protection is far greater than the cost of prevention.

Protect your assets, your operations, and your bottom line with Brush Copper Plating.

📩 Contact Sterling Impreglon Asia today to find out how we can help you eliminate galling and keep your operations running smoothly.