Marine Industry

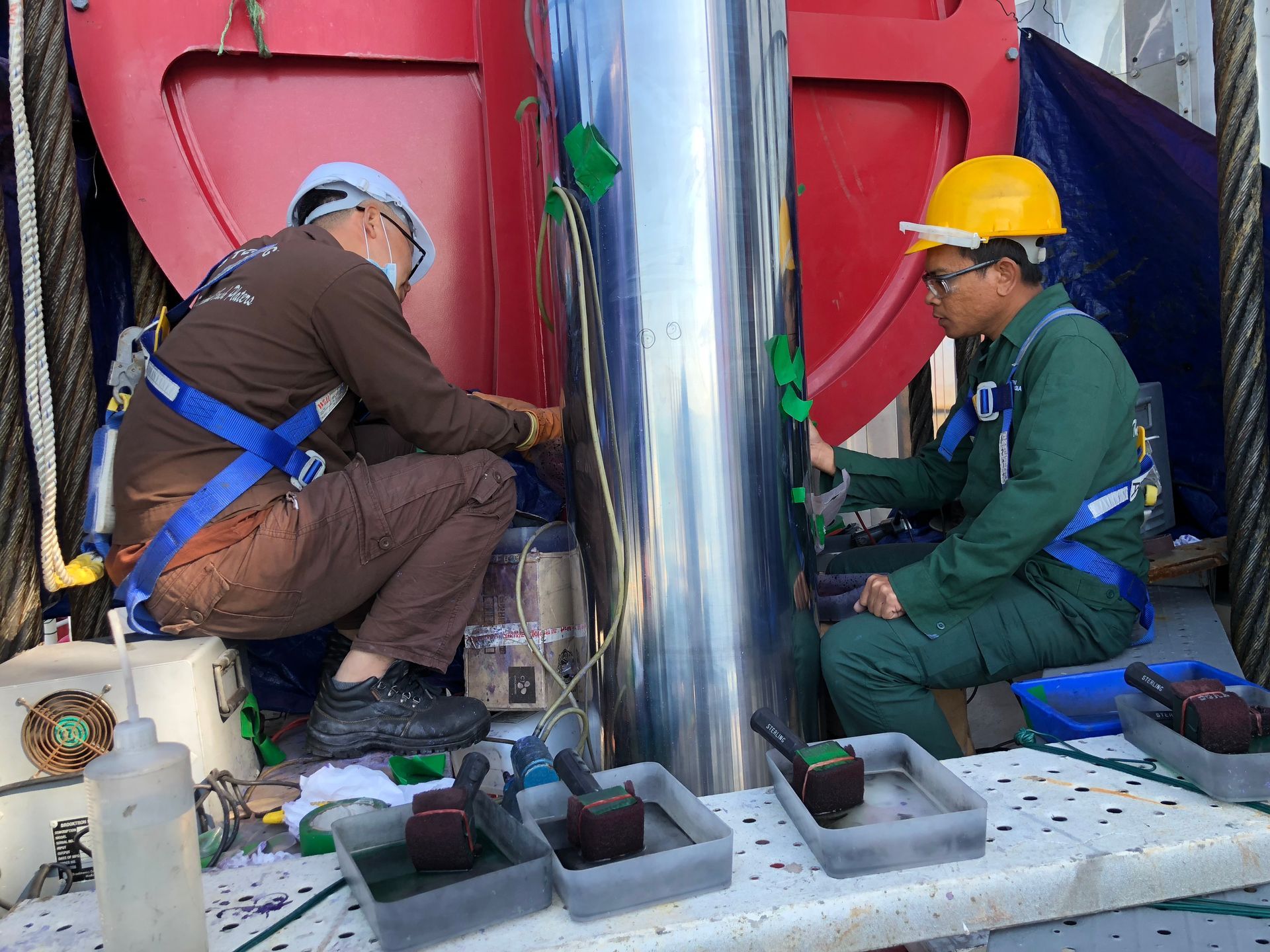

Brush Plating plays a pivotal role in the Marine Offshore Industry, providing essential surface treatments to improve operational performance, reduce unnecessary downtime, and extend the lifespan of marine equipment.

Common Repair for the Marine Industry

Types of Surface Treatments in the Marine Industry

Corrosion Protection

Our Brush Plating techniques create a protective layer on the components, safeguarding them from harsh marine environments and reducing the risk of corrosion.

Wear Resistance

Brush Plating enhance wear resistance on critical parts, increasing their durability and reducing the need for frequent replacements.

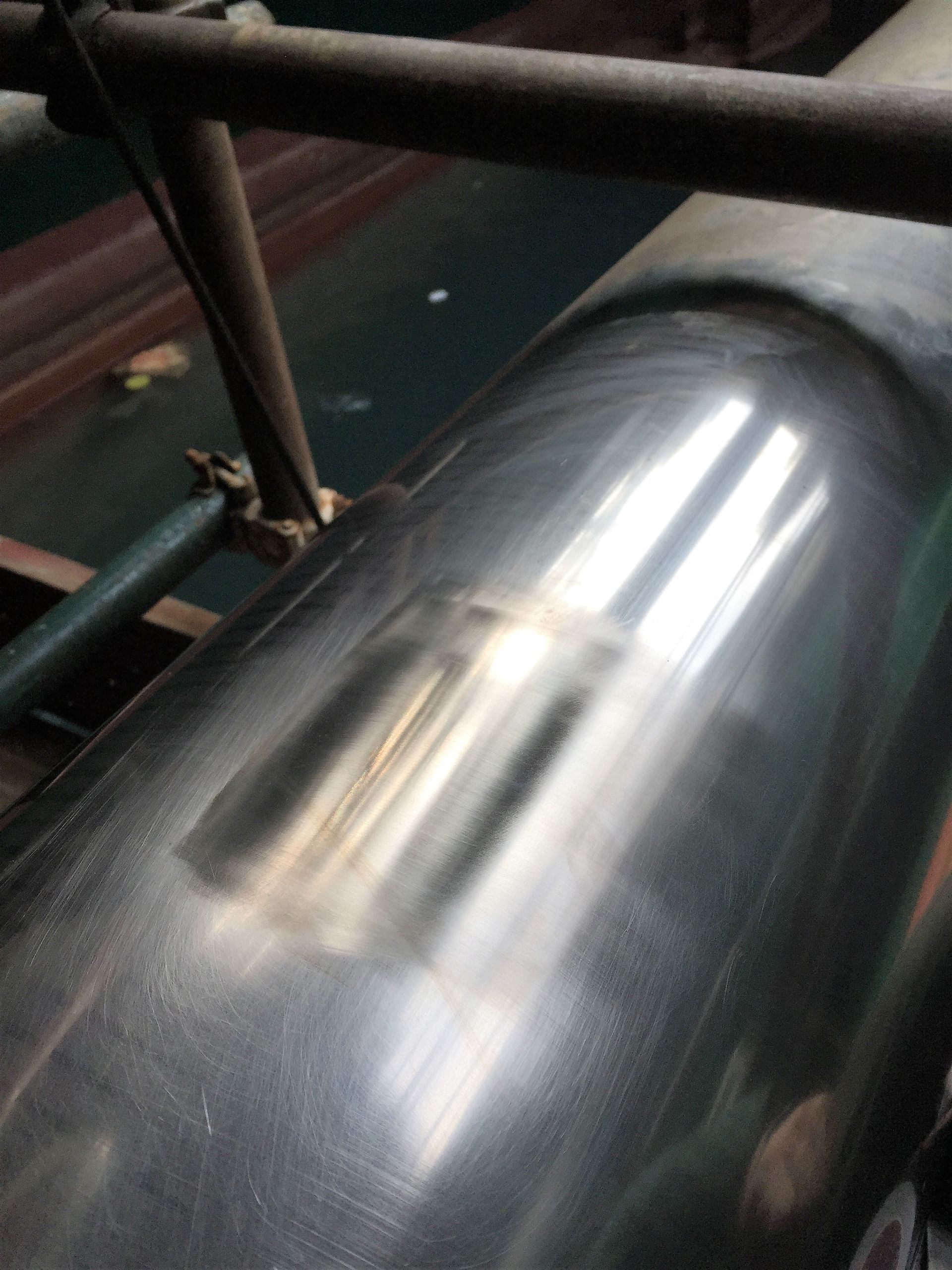

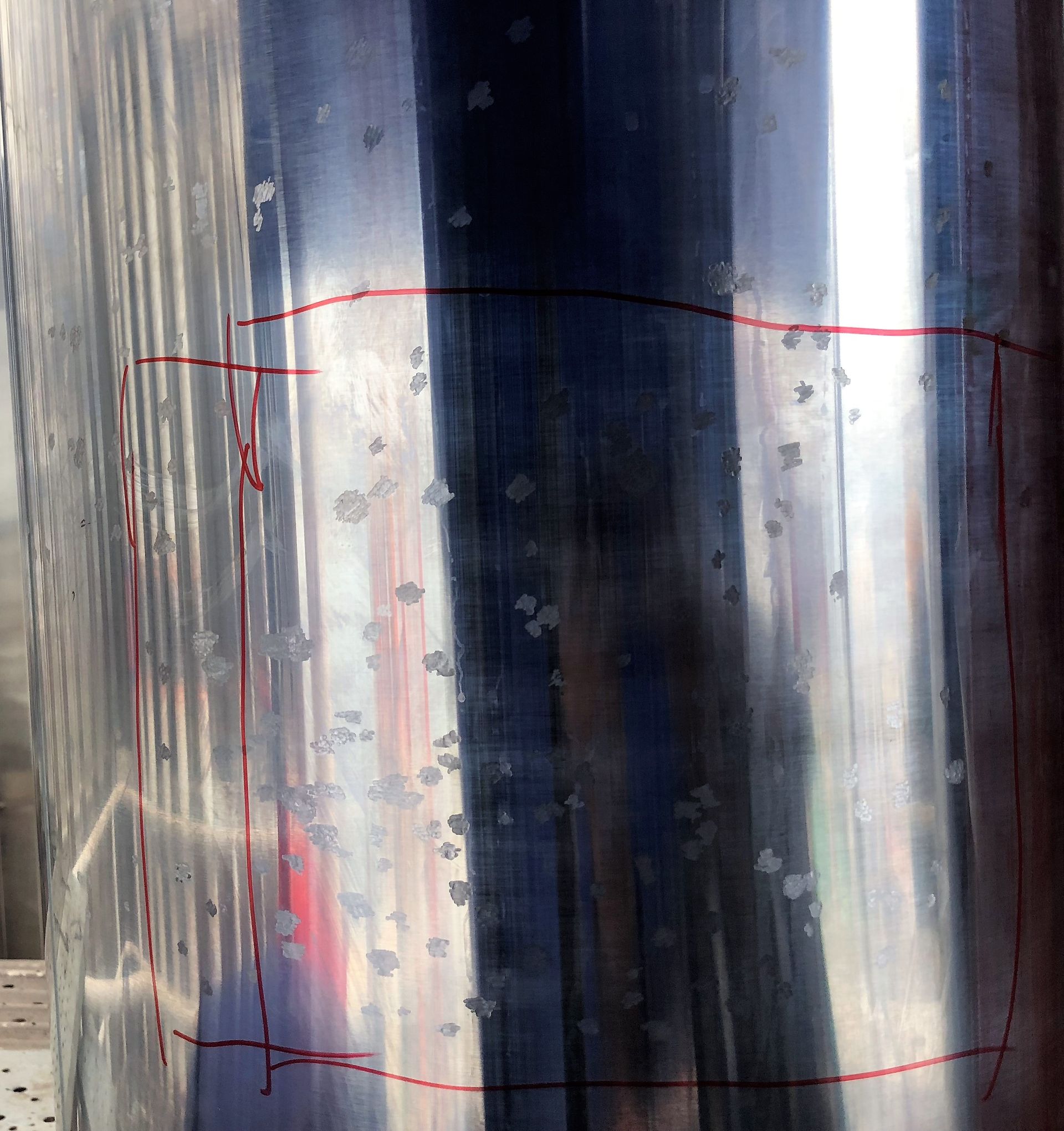

Dimensional Restoration

With Brush Plating being precise and targeted, we can restore worn-out components to their original dimensions and specifications, saving costs and resources for customers.

Excellent Aesthetics

Our Brush Nickel Plating process ensure critical components and equipment are restored to their original pristine condition.