Case Studies

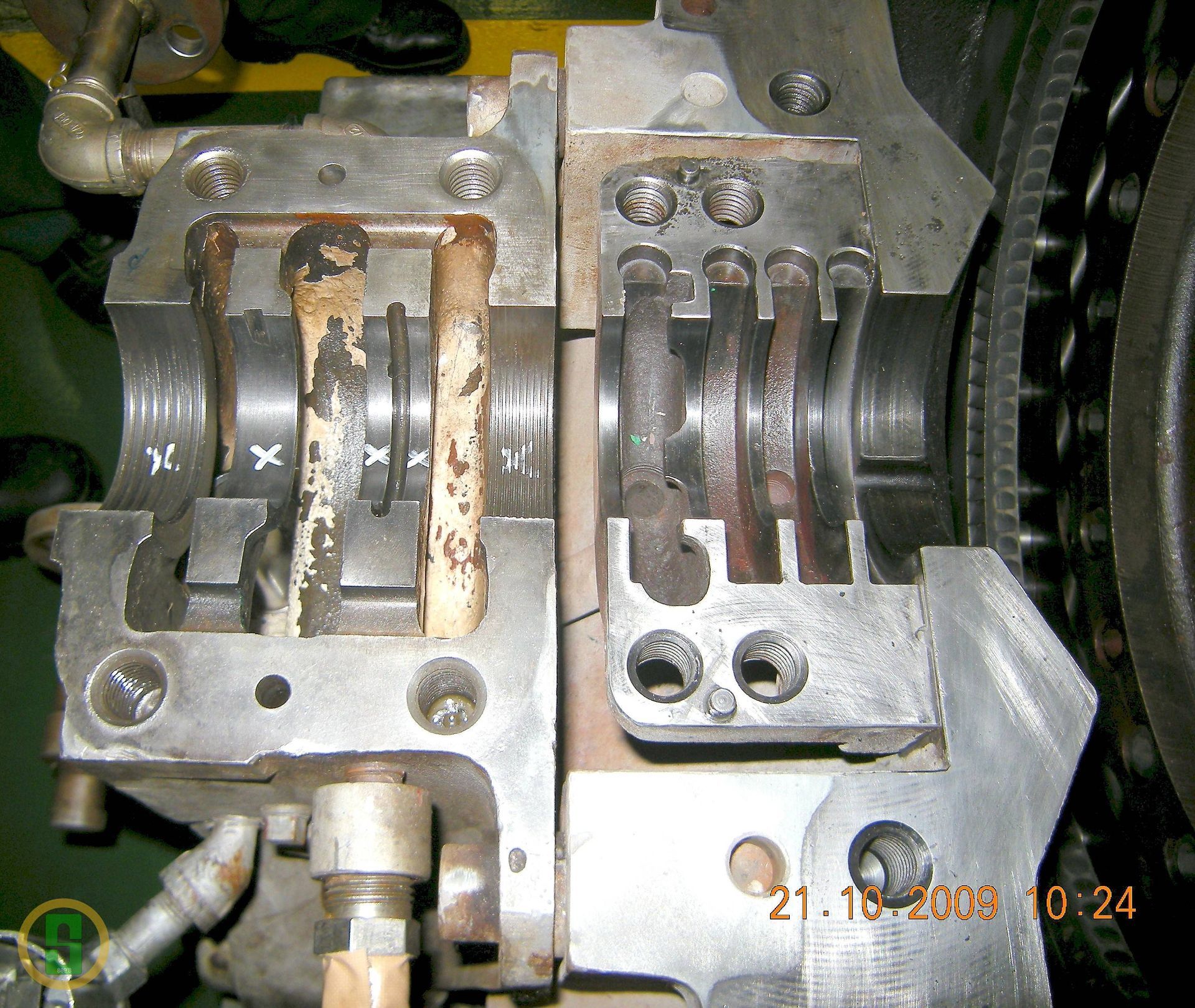

Witness real-life examples where our Brush Plating transformed mechanical components, breathing new life into these critical machineries. These examples not only showcase the versatility of our technology but also underscore its efficacy in restoring, enhancing, and extending the operational life of mechanical components across diverse industries.

Why Choose Sterling Impreglon Asia?

Decades of Expertise

With roots dating back to 1989, our experience is your assurance of quality.

Targeted Solutions

Our precision-focused approach ensures that only necessary areas are restored, saving time and money.

Sustainable Future

Through minimized waste and energy efficiency, we contribute to a greener tomorrow.

Diverse Applications

From turbines to marine components to oil tools connections, we elevate performance of your critical mechanical components across the varied industries.

The Sterling Impact

Critical Maritime Integrity

Our approach preserves the essence of mooring winches, ensuring they stand ready to secure vessels.

Precision Restoration

Each step is a promise of structural resurrection, minimizing downtime, reducing unnecessary costs, and optimizing function.

Global Maritime Reach

With a legacy spanning decade, our contributions extend across oceans and maritime industries.

Advantages of Sterling's Brush Plating Technology

Precise Restoration

Original dimensions, seamless blend, and precise alignment for optimal performance.

Meticulous Attention to Details

No job is too large or complex for our team's expertise. Moreover, our stringent checks guarantee that the restored component meets the required dimensions.

Partner with Sterling Impreglon Asia

Whether it is marine components, heavy industrial machines, or beyond, our Brush Plating technology restores life to mechanical components.