Brush Plating Under Pressure : How It Performs in Harsh Environments

A Proven Solution for Oilfield, Marine, and Heavy Industrial Applications

In today’s industrial landscape, components must withstand extreme environments—from offshore oil rigs and marine vessels to construction equipment and high-speed manufacturing lines. These conditions push mechanical parts to their limits, exposing them to pressure, corrosion, abrasion, and constant wear.

When performance under pressure matters most,

Brush Plating stands out as a reliable, precision-engineered solution.

🔧 What Makes an Environment “Harsh”?

In engineering terms, harsh environments typically involve:

🌊 Corrosive conditions (e.g. seawater, chemicals, drilling mud)

🔥 High operating temperatures or rapid thermal cycling

💥 High pressures in subsea or downhole applications

🔄 Mechanical friction and repeated load cycles

🌪 Exposure to sand, salt, and other abrasives

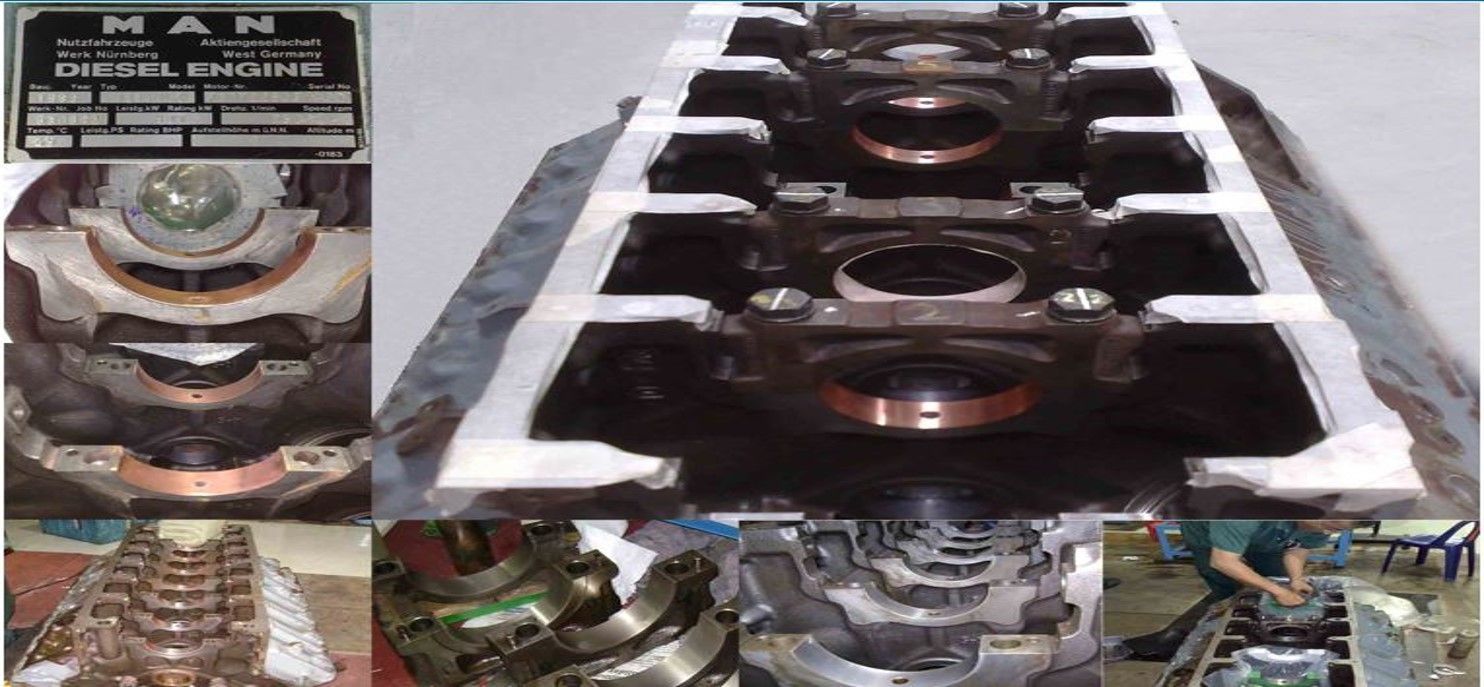

These conditions quickly deteriorate metal surfaces—especially in hydraulic systems, OCTG threads, engine blocks, and industrial rollers.

🛠 How Brush Plating Performs in These Conditions

At Sterling Impreglon Asia, our Brush Plating process is specifically engineered to restore and protect components operating in high-stress environments.

✅ High Bond Strength

Our plating process delivers adhesion strength of up to 132,000 PSI

This means no flaking, peeling, or separation—even under high torque or pressure

✅ Corrosion Resistance

Metals like copper and nickel are selectively plated for corrosion protection

Commonly applied to subsea tools, offshore shafts, and OCTG connections

✅ Precision Application in Complex Geometries

Ideal for plating internal threads, sealing surfaces, and narrow recesses

Unlike tank plating, Brush Plating can target hard-to-reach areas without overcoating

✅ Low-Temperature Process

Operates at ~65°C, eliminating thermal distortion

Safe for delicate or heat-sensitive components, including thin-walled parts

✅ Real-World Testing

Each job is tested using High-Pressure Water Jet Testing (200 bar) and adhesion tape testing to ensure quality and durability

🌍 Field-Proven Across Industries

Brush Plating has been successfully applied in:

🔹

Oil & Gas – Anti-galling protection for

premium and non-premium OCTG threads, crossovers, and downhole tools

🔹

Marine & Offshore – Restoring

hydraulic shafts, cylinder rods, and propeller shafts exposed to seawater

🔹

Construction & Heavy Equipment – Repairing

boom arms, hydraulic pistons, and wear surfaces under constant mechanical load

🔹

Manufacturing – Rebuilding

printing cylinders and rollers subject to friction and chemical exposure

💡 Why It Matters

When you are operating in harsh environments, you need a repair and protection solution that:

✔

Withstands pressure, corrosion, and wear

✔

Minimizes downtime

✔

Extends equipment life

✔

Delivers consistent results you can trust

Brush Plating meets these demands—time and time again.

📩 Need a Solution Built for Tough Conditions?

Sterling Impreglon Asia specializes in Brush Plating that performs where others fail. Whether you are in the field or at the dock, we help you protect and extend the life of your critical components.

💬 Contact us today to learn how we can help your operations perform under pressure.