Why Repair is Smarter than Replacement

Cost-Saving Solutions for Hydraulic Shafts and Rods

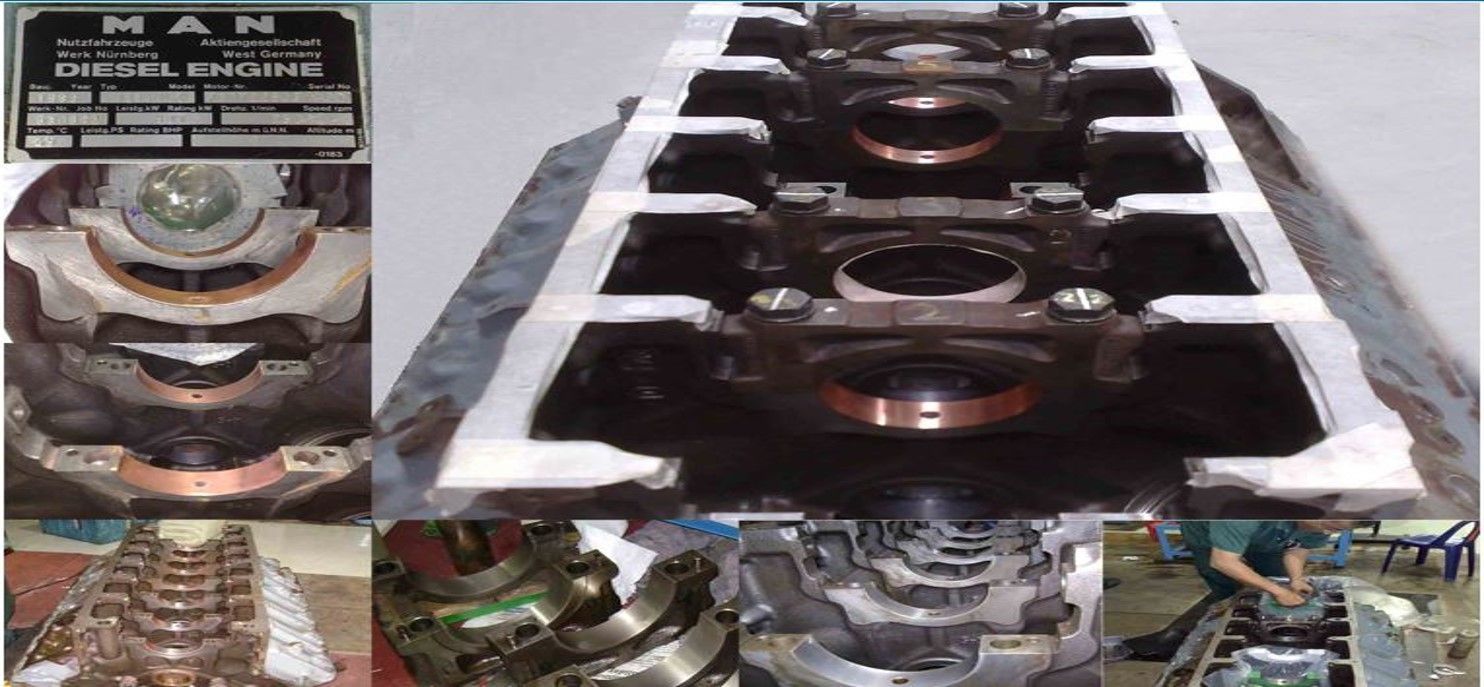

In industries like Marine, Heavy Equipment, and Construction, maintaining operational efficiency is critical. Damaged hydraulic shafts or rods can lead to costly downtime and operational delays. While many companies rely on spare parts or hard chrome plating for repairs, these methods often overlook long-term cost-efficiency, durability, and environmental impact.

Our Brush Plating process – a proven solution for restoring damaged hydraulic components either on-site or in our workshop. This approach delivers precision, durability, and significant cost savings.

The Challenge: Common Practices Are Costly and Unsustainable

Many companies maintain spare hydraulic shafts and rods to minimize downtime. When a part is damaged, they often:

😢 Replace it with a spare and scrap the damaged component.

⛏ Send it for hard chrome plating, which has potential adhesion issues and often higher cumulative costs.

🦴 For smaller components, cutting steel pipes and welding might seem like a quick fix. However, these methods can lead to additional long-term expenses and inefficiencies.

Why Brush Plating Is the Superior Solution

Sterling Impreglon Asia’s Brush Plating technology offers numerous advantages over traditional methods:

✔ Cost Savings:

Restoring damaged hydraulic rods with Brush Plating is significantly more affordable than purchasing replacements, especially for larger components.

Eliminates the need for costly inventory of spare parts.

✔ Minimal Downtime:

Repairs can be performed on-site, reducing the need for transportation and drastically minimizing equipment downtime.

👍 Durability and Quality:

Brush Plating ensures excellent adhesion to the base material, effectively addressing wear and tear, scorelines, and corrosion pitting.

Provides a robust, long-lasting bond, restoring components to their original dimensions.

🎉 Sustainability:

Repairing components instead of replacing them reduces waste, aligning with global environmental standards.

Case Studies: Real Savings with Brush Plating

One of the biggest heavy equipment providers in Singapore sent us a hydraulic shaft with extensive wear and tear and scorelines. Through Brush Plating, the shaft was repaired quickly and efficiently. The result? A fully restored, durable component at a fraction of the replacement cost.

They not only saved money but also experienced minimal disruption to their operations, demonstrating the power of Brush Plating to reduce downtime and enhance efficiency.

Choose Smarter, More Sustainable Repairs

At Sterling Impreglon Asia, we specialize in helping companies save time, money, and resources. Whether it is on-site repair or workshop restoration, our Brush Plating process is tailored to meet your needs with precision and reliability.