Real ROI: How Much Can You Save with Brush Plating?

A Smarter Investment for Industrial Maintenance & Repair

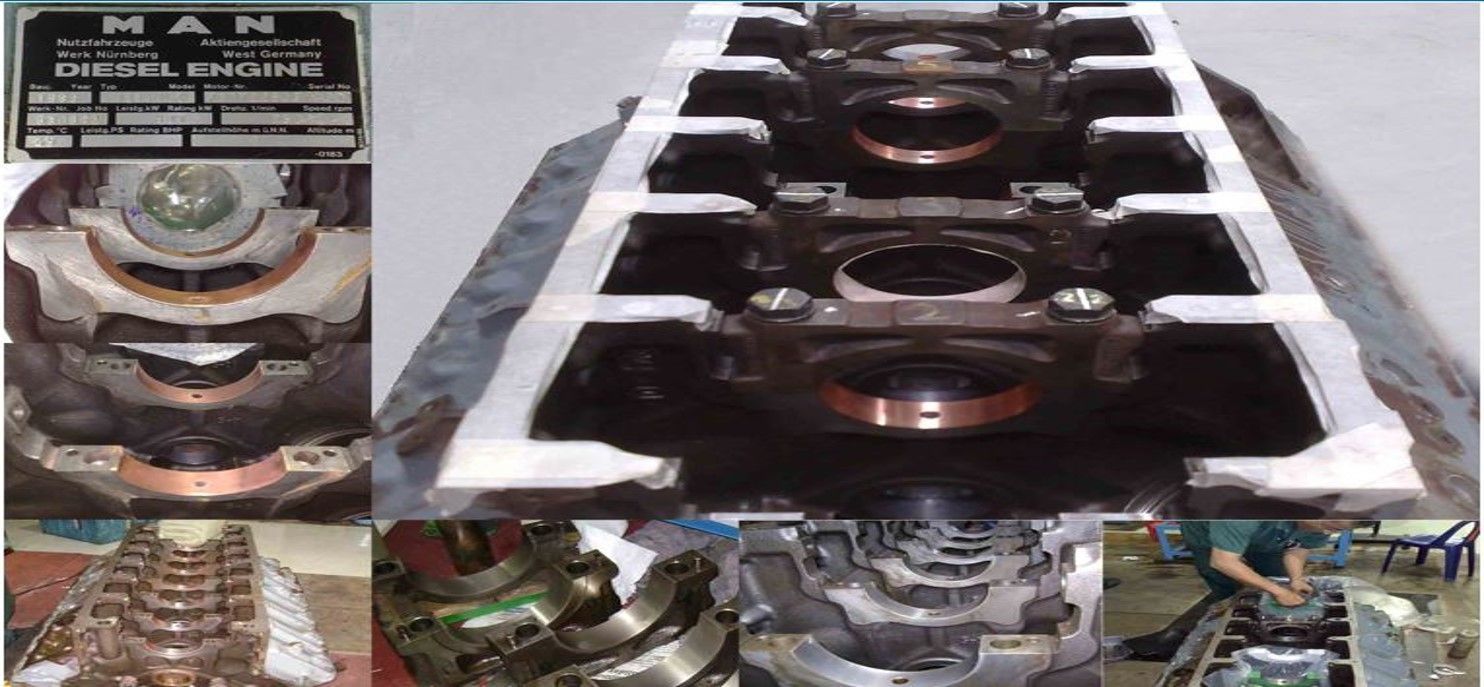

When it comes to maintaining critical components in

marine, oil & gas, offshore, construction, and manufacturing sectors, cost-saving is more important than ever. With rising prices, long lead times, and unpredictable supply chain delays, companies are rethinking their approach to equipment repair.

Enter Brush Plating—a proven, precision repair solution that delivers real return on investment (ROI) by restoring damaged parts instead of replacing them.

💸 The True Cost of Traditional Repairs & Replacements

Let us break down where traditional methods often lead to hidden expenses:

🔧

New Component Procurement

– Large components like hydraulic shafts or OCTG accessories can cost thousands to replace—and that is before factoring in taxes, freight, and customs.

⏳

Downtime Costs

– Waiting for parts to arrive (especially during global shipping delays) means equipment sits idle, costing your business in productivity losses.

🛠

Labor-Intensive Disassembly

– Removing large components for off-site repair or replacement adds man-hours and delays.

♻️

Material Waste

– Replacing an entire part for a localized defect results in unnecessary scrap and waste.

✅ Where Brush Plating Delivers ROI

✔

Component Restoration vs. Replacement

– Brush Plating rebuilds worn, scored, or pitted surfaces back to OEM tolerances—saving up to 70–80% of the cost of a new part.

✔

Faster Turnaround = Less Downtime

– Repairs can often be done

on-site, allowing for

immediate return to service and avoiding weeks or months of downtime.

✔

Selective & Precise

– Only the damaged areas are treated, reducing material use and extending the overall lifespan of the component.

✔

Enhanced Performance

– Our copper and nickel Brush Plating coatings offer

high adhesion, corrosion resistance, and extended durability, preventing future failures.

📈 Beyond Cost: Long-Term Value

Brush Plating does not just save money—it extends your asset’s useful life, supports sustainable operations by reducing waste, and reduces the need for large inventories of spare parts.

💡 Curious What You Could Save? Let Us Talk.

Every repair scenario is different. Contact Sterling Impreglon Asia for a quick consultation and find out how Brush Plating can unlock significant ROI