Proven Strength: Brush Plating That Withstands Extreme Pressure

High Pressure Water Jet Test on Brush Plating

In industries where durability and reliability are critical, adhesion strength is a key factor in choosing a surface coating solution. At Sterling Impreglon Asia, we take quality control seriously—ensuring our Brush Copper Plating can withstand extreme conditions without flaking or peeling.

🔬

High-Pressure Water Jet Test: 200 Bar (132,000 PSI) ✅

After every Brush Plating application, we conduct a high-pressure water jet test at 200 bar (132,000 PSI) to verify adhesion, durability, and overall plating integrity. This rigorous QC check guarantees that our copper plating remains firmly bonded, meeting the highest industry standards.

🌍

Trusted by the World’s Leading Steel & OCTG Manufacturers

Our Brush Copper Plating for anti-galling applications is widely approved by major OCTG steel manufacturers, including:

✔ JFE, VAM, Tenaris

✔ Voestalpine Tubulars GmbH (VAGT), API, Baker Hughes, Hunting – Houston, TPCO-Tianjin, NOV, Schlumberger

✔ BS-Bao Steel Shanghai, TMK Russia, GB of Texas Arai, Halliburton, FMC Energy Services & more

🛠

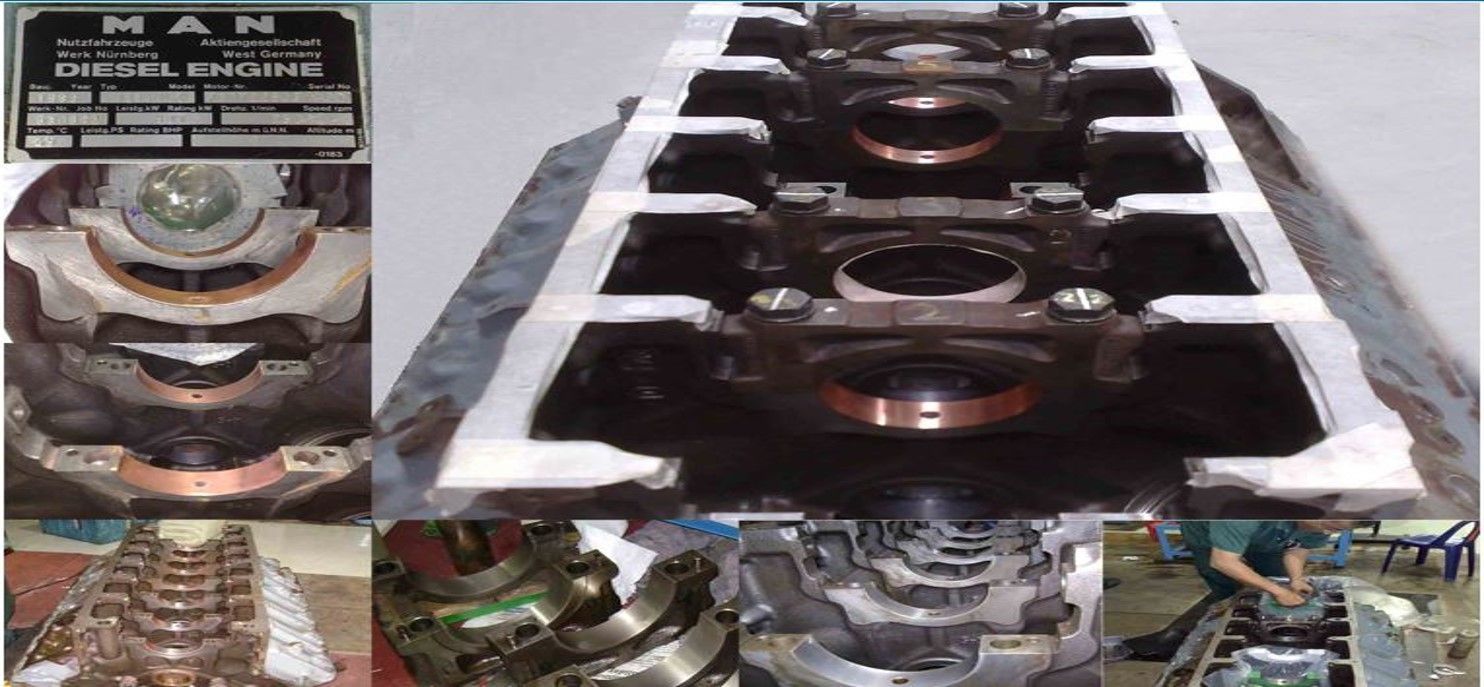

Beyond Anti-Galling: Industrial Repair Applications

Our Brush Copper Plating is not just for OCTG—it also plays a crucial role in industrial repairs, providing:

✅ Excellent adhesion & durability for worn-out mechanical components

✅ Corrosion resistance & longevity for marine, oil & gas, and heavy machinery parts

✅ Precise plating restoration for hydraulic shafts, bearing seats, and other critical components

💡 Looking for a proven, high-quality plating solution? Contact us today to learn how Sterling Impreglon Asia’s Brush Plating can enhance your operations with superior adhesion, durability, and performance.