🔩 Proven Adhesion. Trusted Performance. Why Our Brush Plating Stands Out for OCTG Connection

3 Types of Adhesion Tests for our Copper Plating

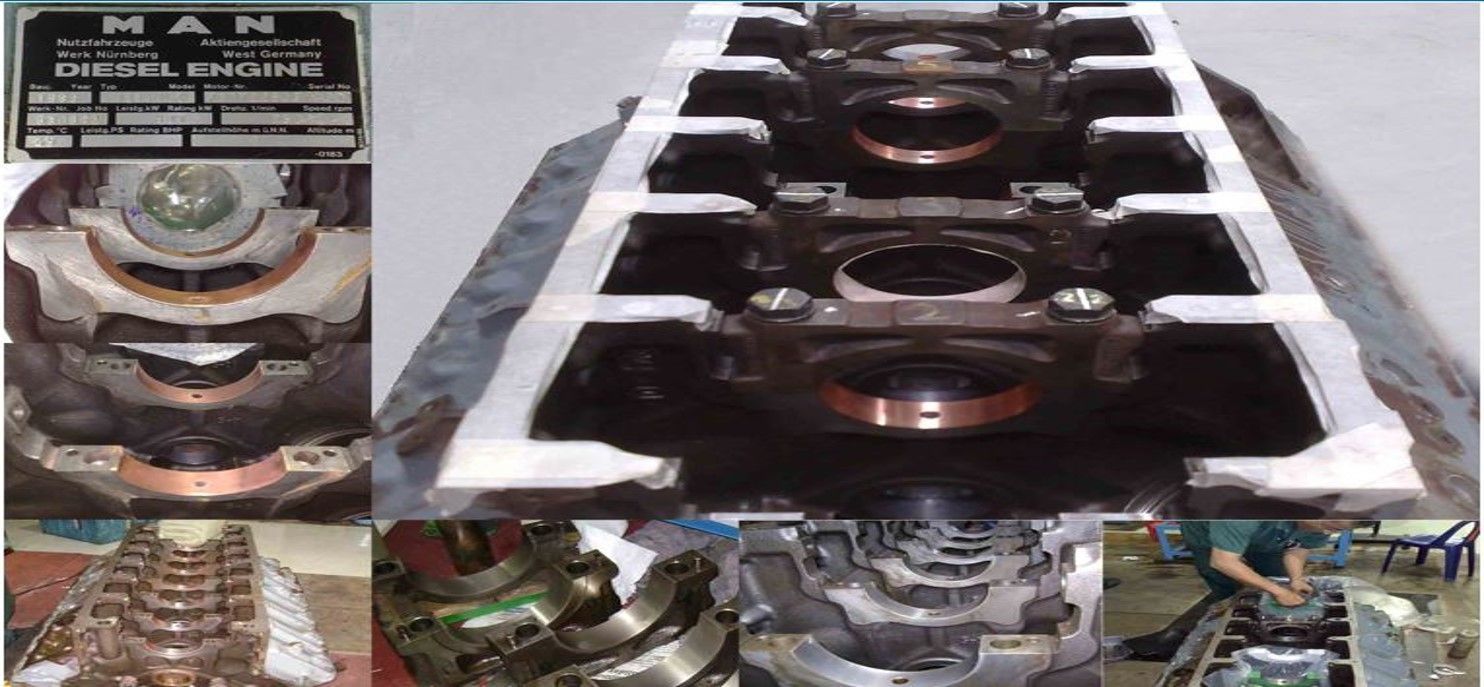

At Sterling Impreglon Asia, our commitment to excellence goes far beyond just applying copper to metal surfaces — we deliver certified performance. With over three decades of experience and global recognition, our proprietary Brush Plating process has become the trusted solution for anti-galling applications on premium and non-premium OCTG connections, including those from industry leaders like Vallourec, Tenaris, JFE, and VAGT.

Before any OCTG connection leaves our facility, it undergoes three different but critical adhesion tests to ensure the copper plating is not just visually perfect, but mechanically and physically bonded to withstand the most demanding applications in the oil & gas industry.

🧪 The 3 Pillars of Adhesion Testing We Perform:

✅ 1. Cross Hatch Scratch Test

This is a visual and mechanical inspection where a precision cutter is used to make fine, intersecting cuts (as shown in the image). This exposes the plating to observe if any flaking or peeling occurs at the cross-section.

📷

🛠 Result: Our Brush Copper Plating remains fully intact with zero peeling or lifting, proving strong mechanical bonding to the base substrate.

💦 2. High-Pressure Water Jet Test

A stream of high-pressure water of 2000 bar is jetted directly at the plated surface to simulate aggressive real-world exposure to fluid pressure during operation.

📷

🛠 Result: The plating remains firmly adhered, without any signs of delamination, flaking, or surface disruption — showcasing its ability to endure harsh operational environments.

🩹 3. Tape Pull Test

Industrial-grade tape is pressed firmly against the plated threads and then peeled off sharply. If the plating lacks adhesion, it will lift or leave behind visible copper fragments.

📷

🛠 Result: The tape pulls away cleanly — no copper residue, no peeling — indicating excellent adhesive strength and plating integrity.

🌍 Why This Matters to Our Customers

These tests are not just routine — they are a requirement by leading OCTG manufacturers worldwide to certify plating quality before it is used in high-stress, high-value operations. When your pipe threads are Brush Plated by Sterling Impreglon Asia, you are not just getting a copper coating — you are getting

✅ No flaking.

✅ No premature wear.

✅ No compromise on quality.

Get in touch with us today to learn how our Brush Plating process can protect your assets and reduce your downtime.

📩 DM us or email:

enquiry@sterling.com.sg

🌐 Visit:

www.sterlingimpreglon.com

🔗 Follow us for more technical insights and success stories.