Real-World Applications: Brush Plating in Action

Brush Plating for Industrial Applications in the Real-World

Equipment wear is inevitable in industrial operations, but costly replacements and long downtimes do not have to be. Brush Plating is a fast, precise, and cost-effective solution that restores critical components without disassembly or replacement. Here is how it benefits various industries:

🔹

Hydraulic Shafts & Cylinders (Marine, Offshore, Heavy Equipment)

✅ Repairs scoring, pitting & corrosion

on-site

✅ Restores original dimensions for

extended service life

✅ Reduces downtime by

eliminating full replacements

🔹

Gearbox & Bearing Seats (Manufacturing, Power Generation)

✅ Rebuilds worn bearing seats,

ensuring proper fit

✅ Reinforces load-bearing surfaces for

longer durability

✅ Avoids costly gearbox replacements

🔹

Printing Cylinders & Industrial Rollers (Printing, Packaging)

✅ Restores smooth surfaces for

consistent performance

✅ Wear-resistant coatings extend roller lifespan

✅ Quick,

in-place repairs reduce downtime

🔹

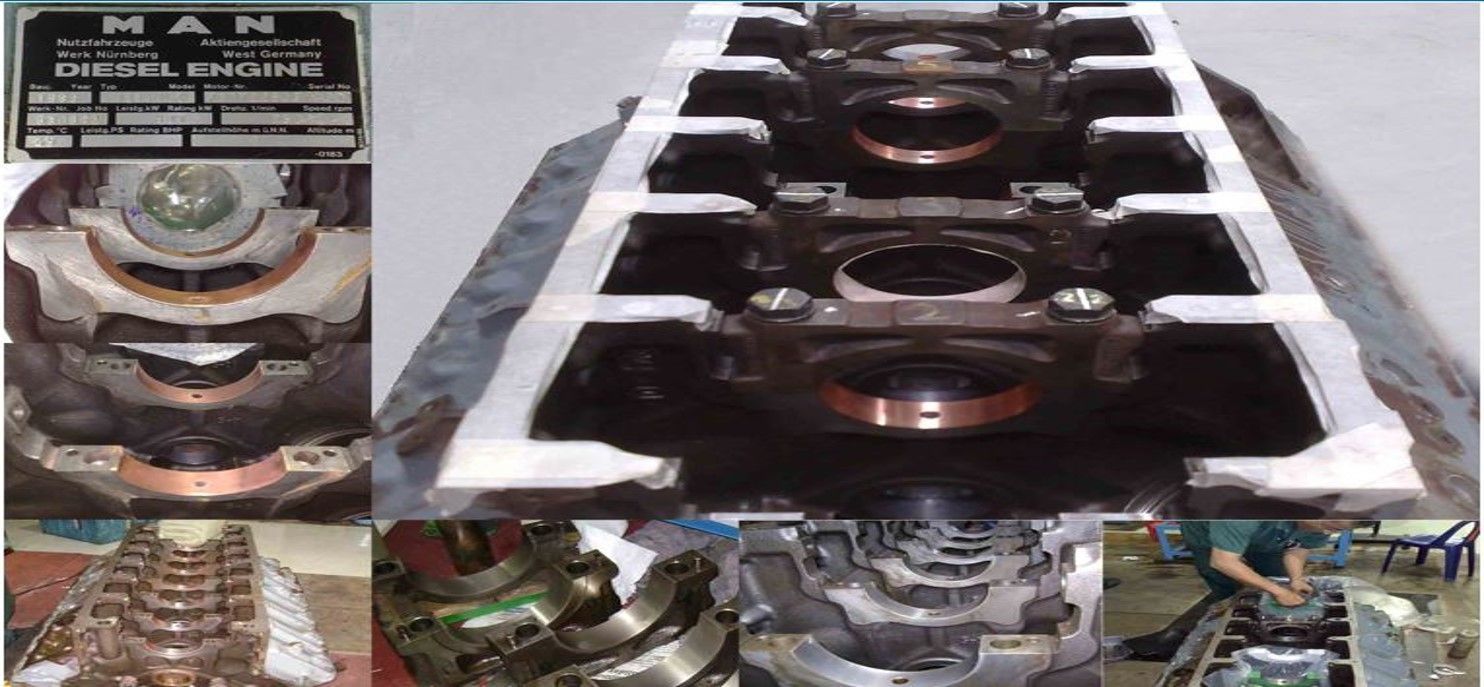

Marine Diesel Engines & Generator Bedplates (Marine, Oil & Gas)

✅ Restores

main bearing saddles & alignment

✅ Prevents thermal distortion vs. traditional welding

✅ Improves engine performance and reliability

🔹

OCTG Connections & Subsea Equipment (Oil & Gas, Offshore Drilling)

✅ Anti-galling copper plating for thread protection

✅ Tested for

high-pressure durability

✅ Ensures smooth make-and-break operations

🚀

Why Choose Brush Plating?

✅

On-site & Workshop Repairs – Less downtime, more efficiency

✅

Stronger Than Conventional Repairs – Bond strength

up to 132,000 PSI

✅

Cost-Effective & Sustainable – Extends component life, reduces waste

🔧 Looking for a better way to repair worn components? Let us talk! Contact us today to see how Brush Plating can revolutionize your maintenance strategy.