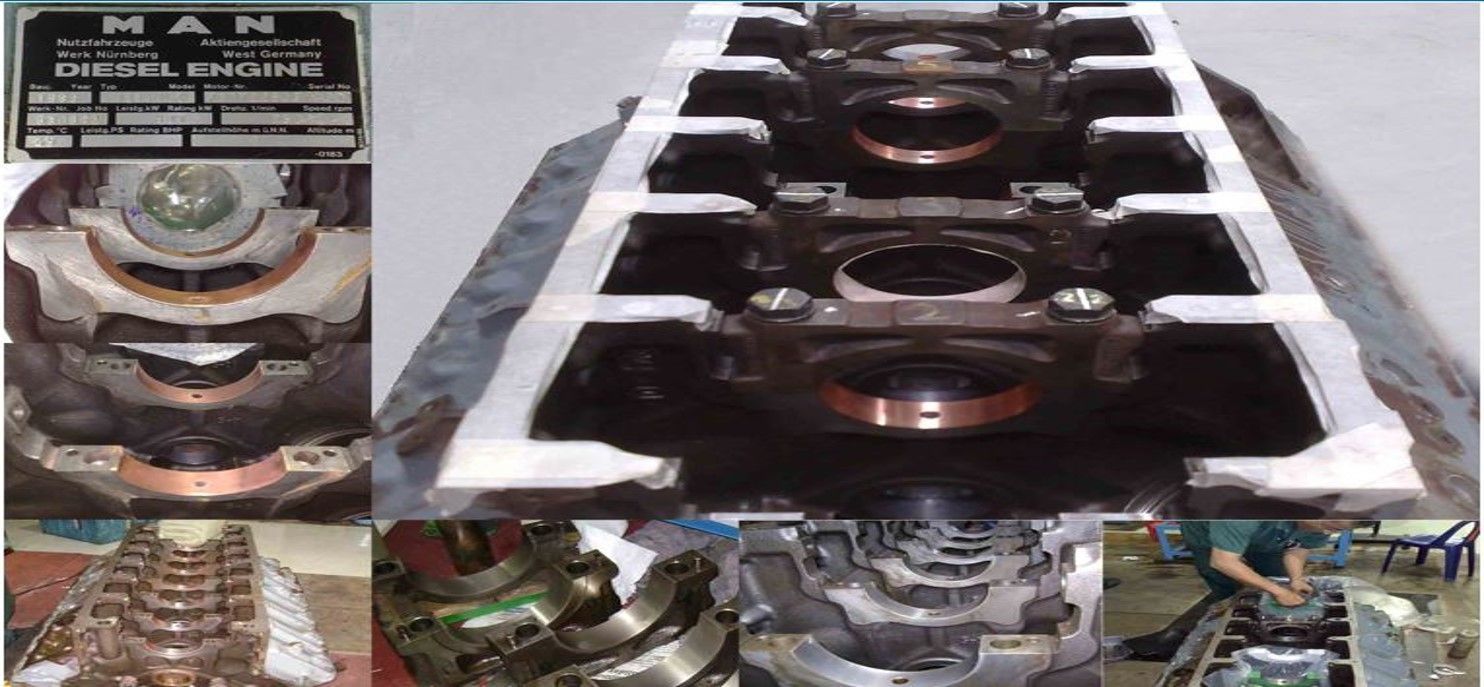

Accumulator Cylinder Repair

Restoring Efficiency On-Site: Accumulator Cylinder Repair Using Brush Plating Technology

At Sterling Impreglon Asia, we pride ourselves on delivering efficient and reliable on-site repair solutions, minimizing downtime and logistics costs for our clients. A recent repair project for an accumulator cylinder perfectly highlights the versatility and cost-saving nature of our proprietary Brush Plating process.

The Challenge:

The cylinder’s

internal circumference suffered from severe

pitting corrosion, impairing its operational efficiency, and rendering it non-functional. A swift and effective repair was critical to restore the component to its original condition.

Our Solution – Step-by-Step Process:

1️⃣ Survey & Preparation

Our experienced technicians conducted a thorough survey to assess the extent of the damage and prepared the necessary tools and materials.

2️⃣ Surface Preparation

We carefully cleaned and opened up the damaged pitted areas—widening without deepening—preparing them for plating.

3️⃣ Brush Copper Plating

Using our precise Brush Plating process, we rebuilt the damaged areas to their

original dimensions. This method ensures minimal material removal while achieving

superior adhesion.

4️⃣ Finishing & Blending

Post-plating, our team hand-blended the repaired areas to ensure a seamless finish, perfectly even with the surrounding surface.

5️⃣ Nickel Capping

To further enhance

corrosion and

wear resistance, we applied a protective layer of

nickel capping. The result? A durable repair that looks as good as

brand new.

6️⃣ Quality Assurance

We conducted comprehensive

adhesion tests and final

dimensional checks to ensure the repair work met customer specifications and standards.

The Result:

✅ The cylinder was fully restored, delivering renewed efficiency.

✅ Downtime was minimized thanks to our

on-site repair capabilities.

✅ The customer achieved significant savings by avoiding costly replacements.

With over 30 years of experience, Sterling Impreglon Asia’s Brush Plating solutions continue to set the benchmark for precision repairs in mechanical components—be it hydraulic cylinders, gearbox components, or marine engines.

🔗

Want to reduce downtime and repair costs for your critical equipment?

Reach out to us today to learn how

Brush Plating can restore your components efficiently, anywhere.