How Brush Plating Complements Metalocking Repairs

The Complete Solution for Structural and Surface Restoration

In industries where

heavy machinery, large castings, and critical components are at the heart of operations, equipment damage is inevitable. Cracks, fractures, wear, and corrosion often occur under extreme operating conditions. While

Metalocking (metal-stitching) is the go-to solution for restoring structural integrity to cracked or fractured components, it does not fully address issues related to

surface wear, precision fit, and corrosion resistance.

That is where Brush Plating comes in—providing the perfect complement to Metalocking by restoring and enhancing the functional surfaces of the repaired part.

🛠 The Role of Metalocking: Restoring Structural Integrity

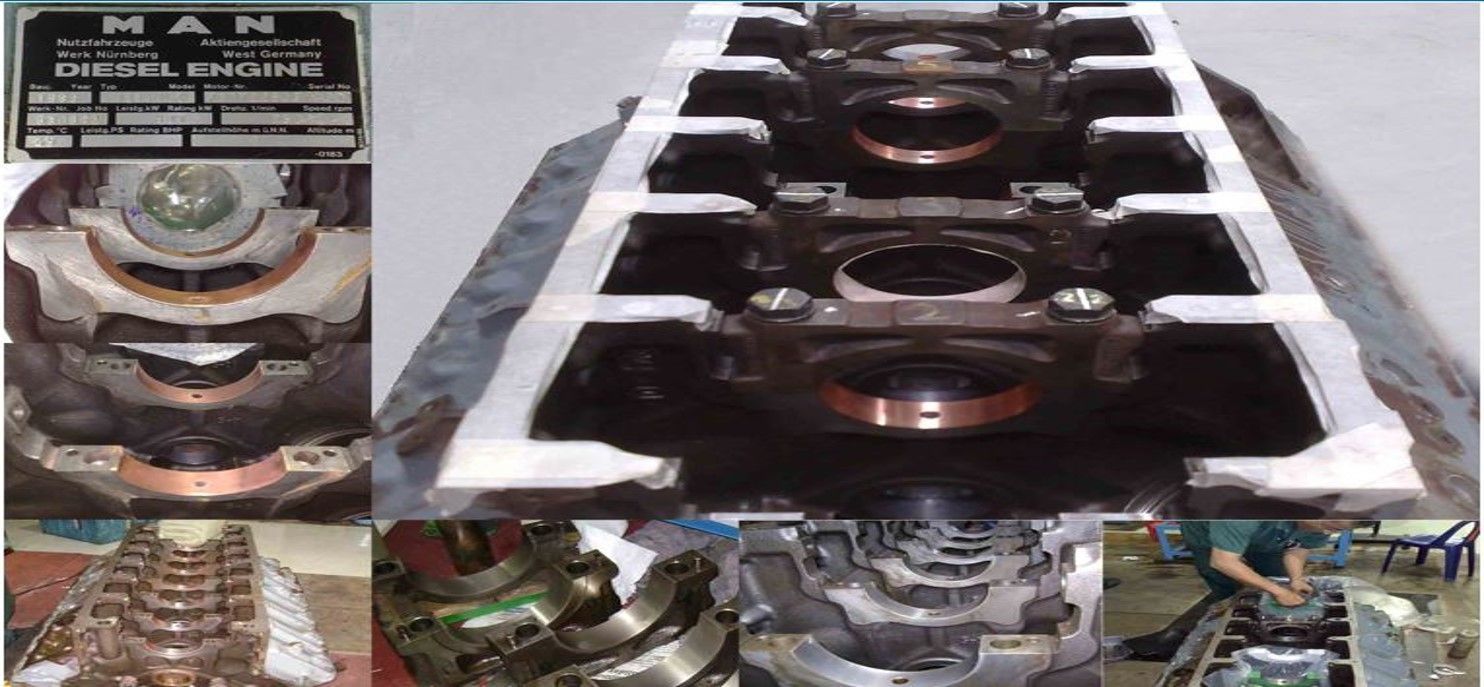

Metalocking is highly effective for repairing cracks in cast iron, cast steel, and aluminum components without introducing heat or distortion. It restores the mechanical strength of components such as:

- Engine blocks and cylinder heads

- Turbine casings and compressors

- Large gearbox housings

- Marine diesel engines and bedplates

However, while Metalocking repairs the structural damage, it does not restore worn surfaces, precise fits, or sealing faces—areas critical for ensuring the operational performance and efficiency of the equipment.

⚙️ How Brush Plating Complements the Process

After a Metalocking repair, the affected component may still require:

- Rebuilding of worn bores and bearing seats

- Restoration of sealing faces and gasket surfaces

- Corrosion protection of exposed metal surfaces

- Precision build-up for proper alignment and tolerances

Brush Plating is the ideal solution to address these challenges:

✅

Precision Surface Restoration

Brush Plating allows technicians to

accurately build up worn surfaces back to their original specifications without the need for extensive machining.

✅

Improved Corrosion Resistance

Applying a protective layer of copper or nickel prevents further corrosion, especially on surfaces exposed to harsh environments like

marine, offshore, and industrial settings.

✅

Enhanced Durability & Load-Bearing Performance

Rebuilt surfaces can withstand

high loads, friction, and vibration, ensuring the component remains operational for the long term.

✅

Minimal Downtime, On-Site Capabilities

Brush Plating can be performed

on-site or at your facility, reducing the need for costly transportation and long downtimes.

📈 The Result: A Fully Restored, Functional, and Reliable Component

By combining Metalocking for structural repair and Brush Plating for surface restoration, companies achieve a complete, cost-effective, and long-lasting repair solution. This approach is widely used across industries such as:

- 🛳 Marine & Offshore – Restoring main engine blocks, bedplates, and propeller shafts

- 🛢 Oil & Gas – Repairing cracked pump housings and restoring precision sealing surfaces

- 🏗 Construction & Heavy Equipment – Rebuilding damaged bores and shaft journals

- ⚙️ Manufacturing – Restoring press machine frames, rollers, and bearing housings

💡 Conclusion: Why Settle for Half a Solution?

A structurally repaired component that fails due to worn surfaces or poor fits is a missed opportunity. By combining Metalocking with Brush Plating, you achieve not only a structurally sound repair but also a functional, precise, and durable component ready to return to full operation.