Enhancing Construction & Heavy Equipment with Brush Plating

Construction & Heavy Equipment with Brush Plating

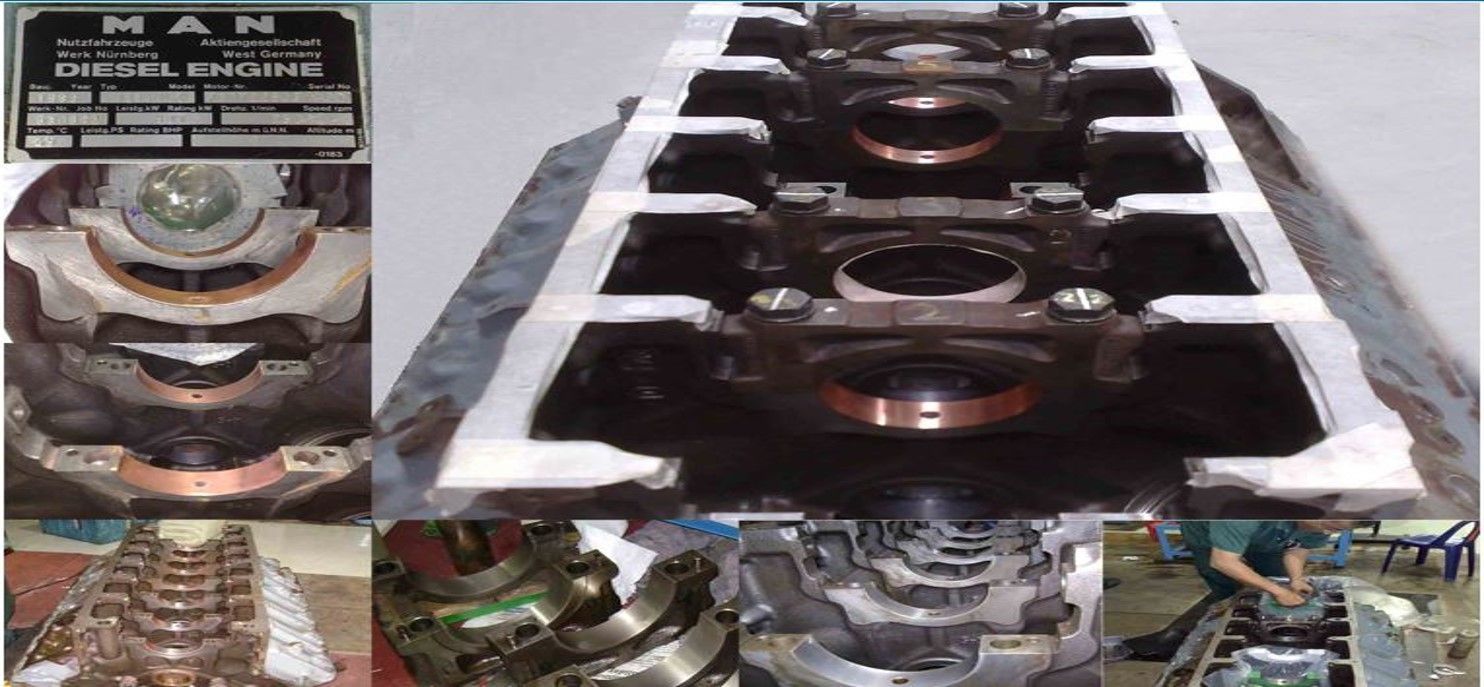

In the construction and heavy equipment industry, machinery is constantly subjected to extreme stress, abrasive environments, and heavy-duty cycles. Over time, critical components like hydraulic shafts, boom cylinders, bearing housings, and gear shafts begin to show signs of wear, scoring, pitting, and corrosion.

These damages, if left unaddressed, can lead to equipment breakdowns, project delays, and high replacement costs. At Sterling Impreglon Asia, our Brush Plating technology offers a smart, fast, and cost-effective solution to repair and restore these components to their original specifications—without the need for full replacements.

🔧 Common Challenges in Heavy Equipment Maintenance

✔

Scorelines & Surface Wear – Caused by metal-to-metal contact, debris intrusion, or seal failures on hydraulic rods and shafts

✔

Corrosion & Pitting – Due to exposure to weather, mud, and chemicals on outdoor equipment

✔

Misaligned Bearing Seats – From prolonged stress and wear in gearboxes and moving joints

✔

Downtime Due to Part Replacement Delays – Sourcing large components like boom arms or shafts can take weeks

🛠 How Brush Plating Solves These Issues

Our Brush Plating process allows for selective, precision repair of worn or damaged surfaces—directly on-site or in our workshop.

✅

Restores original dimensions of worn parts without excessive machining

✅

Eliminates the need for costly new components

✅

Minimizes equipment downtime with fast turnaround

✅

Applies durable, corrosion-resistant coatings that extend part life

✅

Ideal for complex geometries that are difficult to access with traditional methods

🚜 Applications Across Construction & Heavy Equipment

🔹

Hydraulic Shafts & Cylinders – Restore scoring and wear for smooth operation

🔹

Boom Arm Telescopic Extensions – Repair and protect exposed shaft surfaces from corrosion and pitting

🔹

Gear Shafts & Sleeves – Rebuild worn fits to ensure proper alignment and load transfer

🔹

Bearing Housings – Resurface damaged bores to eliminate misalignment and premature wear

💡 A Smarter Way to Maintain Your Equipment

Instead of waiting weeks for parts or investing in full replacements, Brush Plating restores your critical components efficiently and effectively—helping you keep your projects on schedule and your equipment in peak condition.

📩 Reach out to Sterling Impreglon Asia today to explore how Brush Plating can support your heavy equipment maintenance strategy.