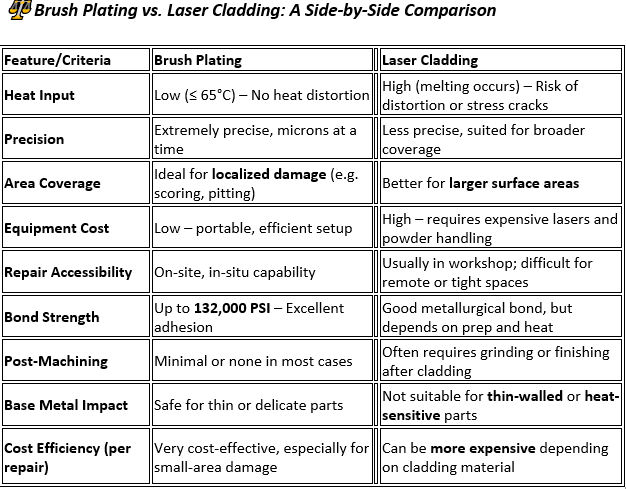

Brush Plating vs. Laser Cladding: Choosing the Right Repair Method for Your Mechanical Components

Understanding the Differences to Make an Informed Decision

As industries face growing pressure to extend equipment life, reduce costs, and minimize downtime, many companies are turning to advanced surface repair technologies. Among the most talked-about methods today is Laser Cladding—often promoted as a fast and high-tech solution for restoring worn mechanical components.

In this article, we will provide a brief introduction to

Laser Cladding, and then compare it to

Brush Plating, helping you understand the differences and why Brush Plating remains a

superior choice in many repair scenarios.

🔧 What Is Laser Cladding?

Laser Cladding is a process where a high-powered laser is used to melt a metal powder or wire onto a substrate (the base metal). As the laser moves, it deposits a new layer of material that bonds metallurgically with the surface below.

It is commonly used for:

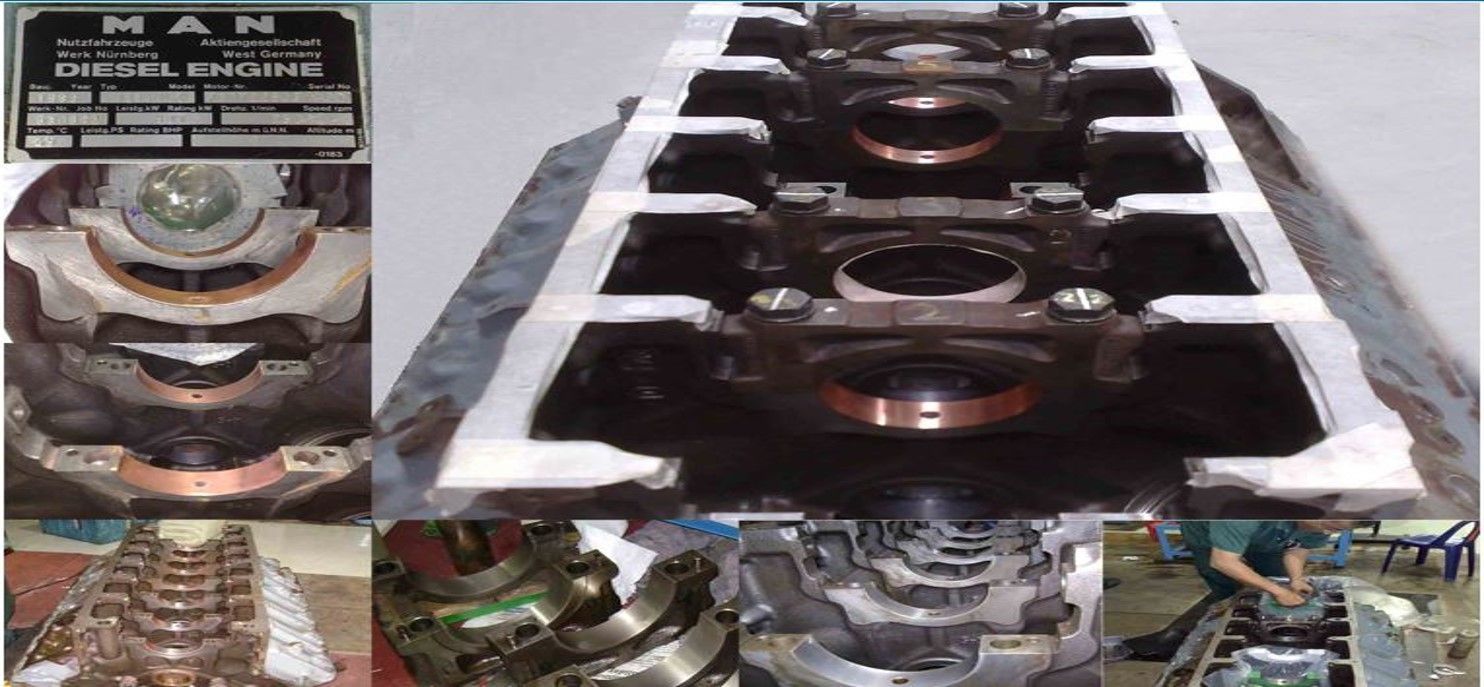

- Coating and repairing shafts, valves, hydraulic rods, and mold surfaces

- Building up worn areas or adding corrosion/wear-resistant materials

- Applications in aerospace, oil & gas, and manufacturing

💡 When Brush Plating Is the Smarter Choice

While Laser Cladding has its place, particularly in large-area wear applications, it is not always the best or most efficient choice—especially for components such as:

- Hydraulic cylinders and shafts with minor wear or scoring

- Printing rollers and sleeves with localized pitting

- Marine components like propeller shafts or bearing seats

- Shaft journals, bores, and threaded areas that require fine tolerance

Brush Plating excels in these cases because it is:

- Fast to deploy

- Cost-effective for small and medium repairs

- Highly accurate for dimensional restoration

- Low-risk, with no damage to the parent metal

🛠 Do not Over-Engineer the Repair

Many customers are turning to laser cladding thinking it's more advanced or cheaper—but "high-tech" does not always mean "better". In fact, Brush Plating can often deliver superior results at a lower cost, particularly for precision repairs and in-situ restoration.

📩 Ready to Restore with Confidence?

If you are considering laser cladding, talk to us first. At Sterling Impreglon Asia, we’ll help you assess whether Brush Plating is a better fit for your repair needs—saving you time, money, and unnecessary complexity.

📞 Contact us today for a free consultation or site visit.