A Brush Plating Success Story on a Printing Cylinder

Restoring Operational Efficiency: A Brush Plating Success Story on a Printing Cylinder

At Sterling Impreglon Asia, we take pride in solving complex mechanical challenges for our customers using our proprietary Brush Plating process. Today, we are sharing a case study showcasing the restoration of a heavily damaged printing cylinder.

The Challenge

The printing cylinder was suffering from severe corrosion pitting, which had significantly compromised its operational efficiency. These defects rendered the cylinder inoperable, creating downtime and financial loss for the customer. The cylinder’s restoration required a precise, durable, and fast repair solution—an ideal scenario for our Brush Plating process.

The Solution

Our expert team followed a meticulous step-by-step approach to restore the cylinder to its original dimensions and performance standards:

👍 Grinding Open the Damaged Area: The repair began with grinding open the corroded and pitted areas using specialized grinders. This ensured complete removal of the damaged material while preparing the surface for the plating process.

✔ Masking and Surface Preparation: To protect the unaffected parts of the cylinder, we masked the surrounding areas with polyethylene (P.E.) sheets. This step also prevented any leakage of chemicals during the plating process. We then thoroughly rinsed and scrubbed the damaged area to remove dirt and impurities, ensuring a clean surface for optimal adhesion.

✔ Pre-Plating Treatment: A crucial part of the process, the pre-plating treatment ensured that the surface was conditioned for a strong bond with the plating material.

👍 Copper Build-Up Process: Using our proprietary Brush Plating process we meticulously applied layers of copper to the damaged areas. This phase required precision to ensure proper build-up and bonding with the base material.

🦴 Smoothing and Blending: Once the copper plating was completed, a belt sander was used to blend and smooth the plated area. This step ensured that the repaired section was level and seamless with the surrounding surface.

👌 Nickel Capping for Final Finish: To enhance durability and match the cylinder’s original appearance, we applied a nickel cap over the copper-plated area. This finishing touch ensured that the repaired section was indistinguishable from the original material.

🎉 Dimensional Inspection: As a final step, we conducted a comprehensive dimensional check to verify that the repair met the customer’s specifications and operational requirements.

The Outcome

The entire repair process was completed in just 4-5 days, minimizing downtime for the customer. The restored printing cylinder not only regained its operational efficiency but also achieved a finish that looked as good as new. Our Brush Plating process provided a durable solution with excellent adhesion properties, ensuring that the repair would withstand the rigors of industrial use.

Why Choose Sterling Impreglon Asia?

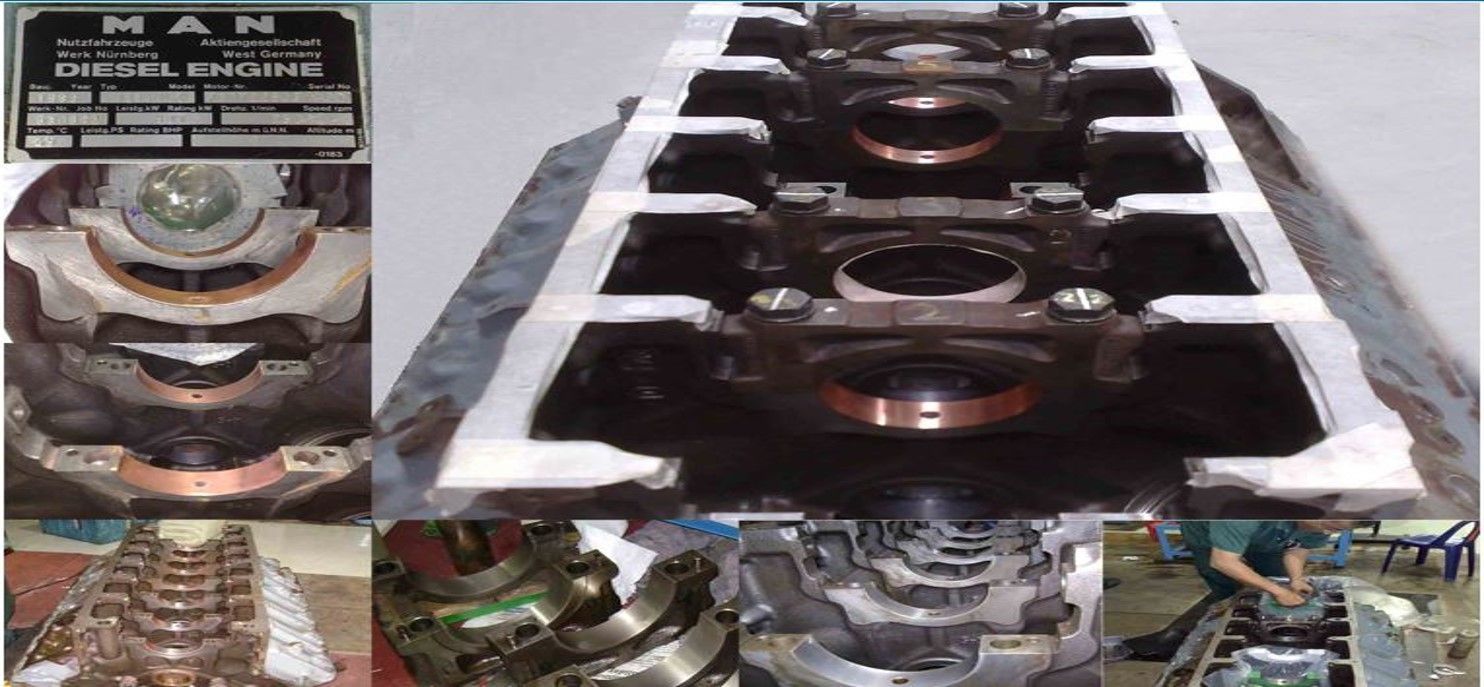

Our Brush Plating technology is a proven and cost-effective solution for repairing damaged mechanical components. From hydraulic shafts to marine diesel engines, we offer on-site and workshop services to address various industrial repair needs. With a reputation for excellence and global recognition, Sterling Impreglon Asia is your trusted partner for precision repairs.