WE PLATE WHERE YOU ARE

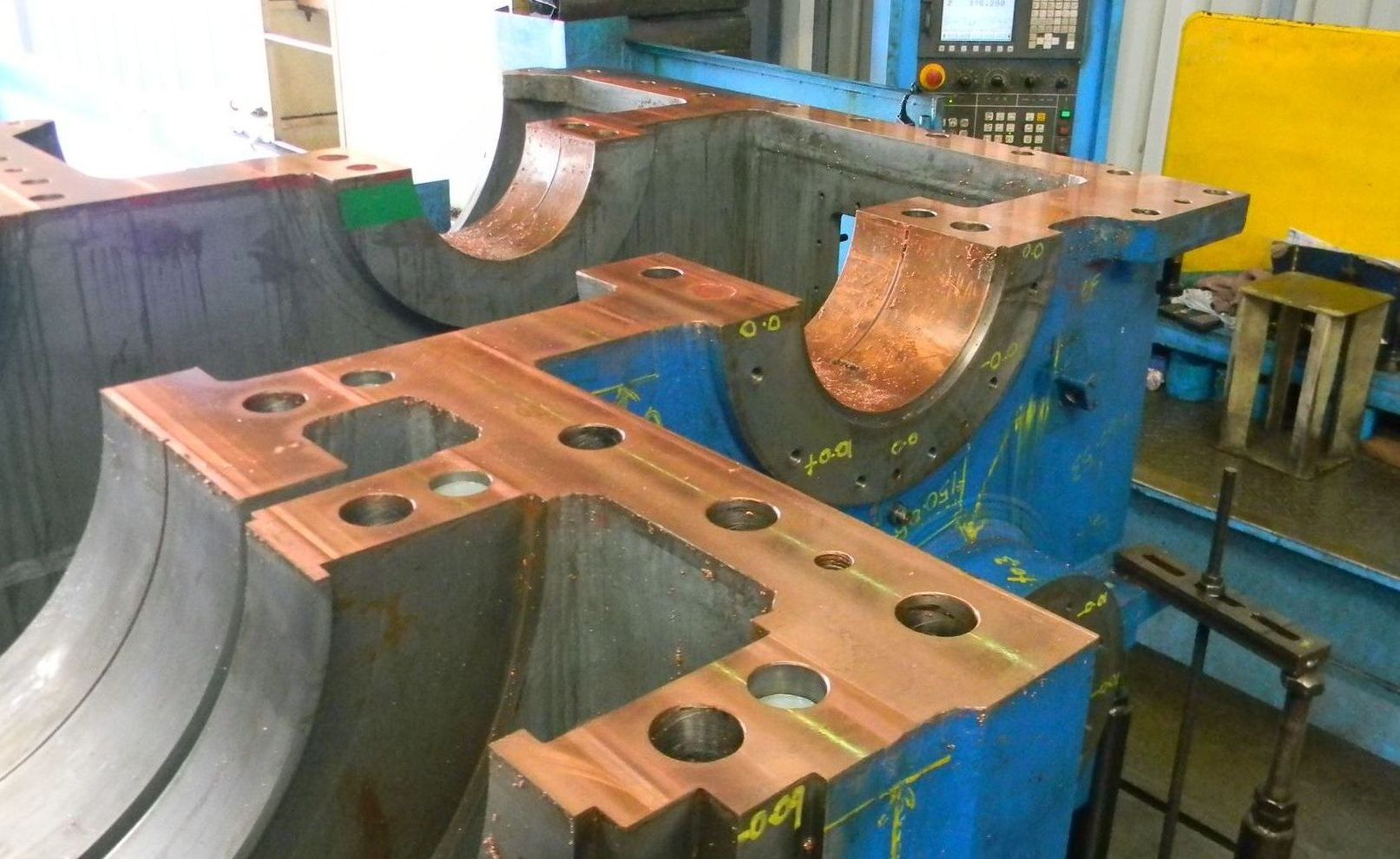

Sterling Impreglon Asia repairs Mechanical Component damages with our unique Brush Plating Process

ISO & Industries Accreditations

Environmentally Sustainable

Efficient & Cost-savings

Accreditations

Brush Plating Technology Applications

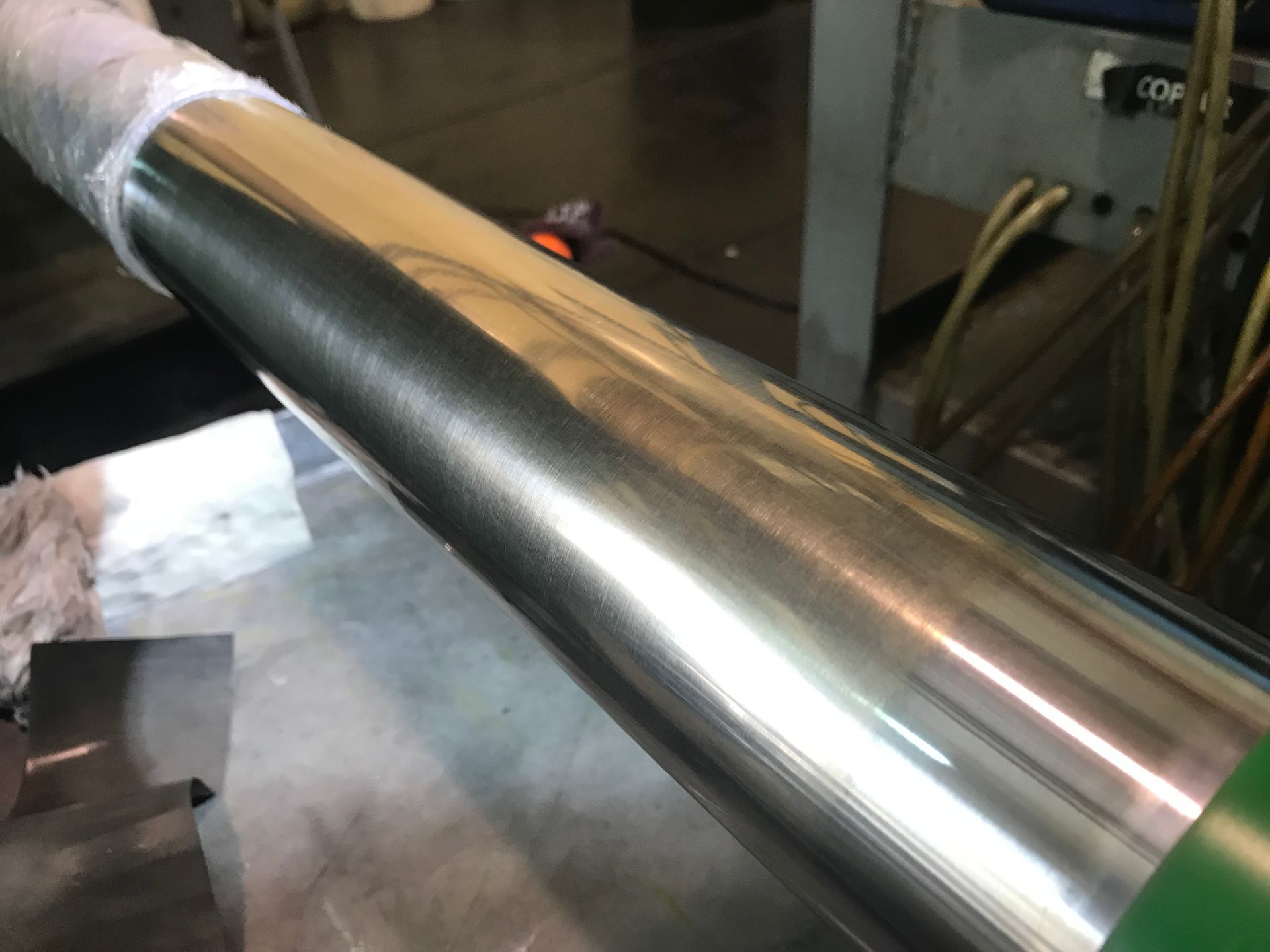

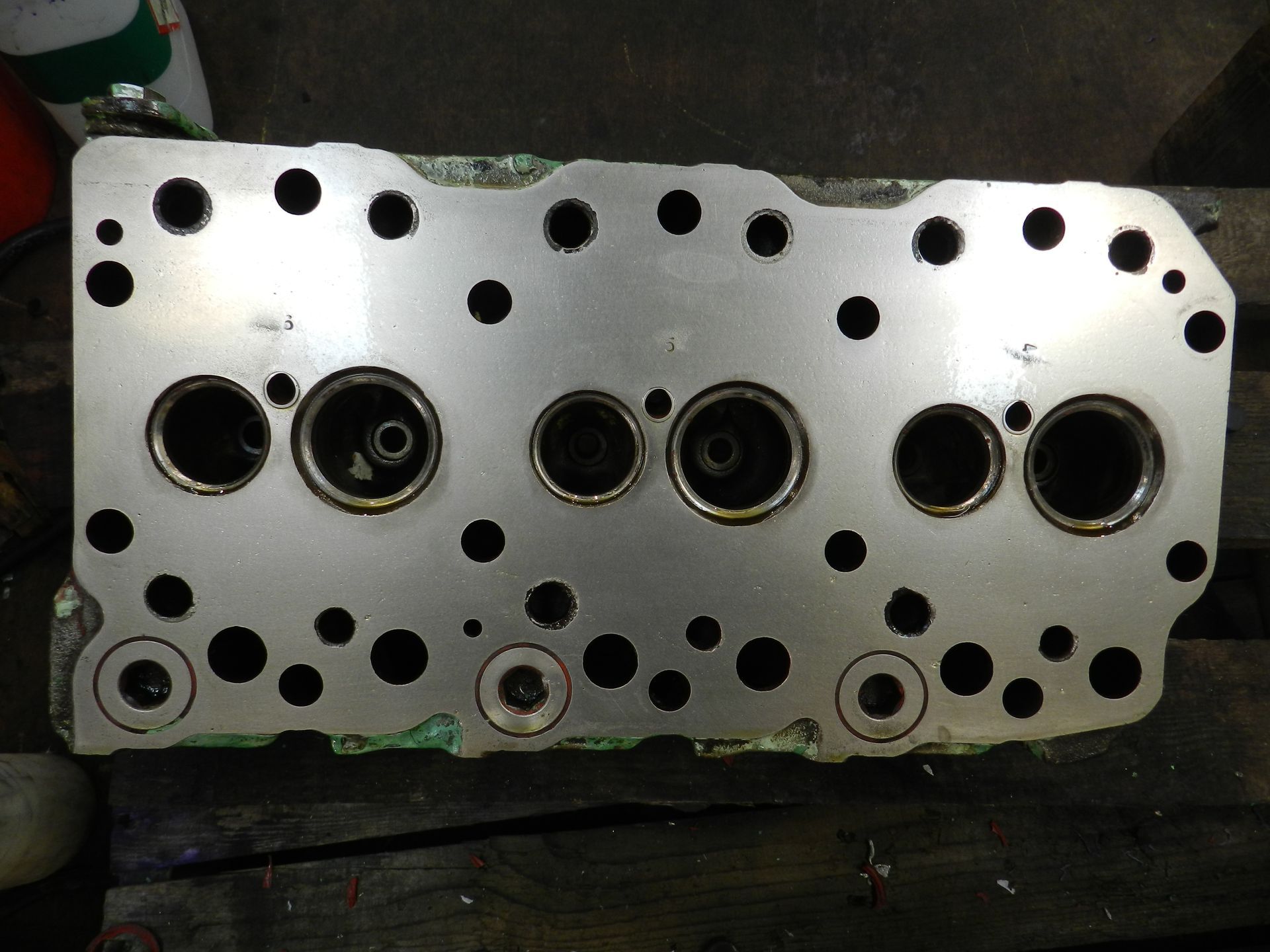

We specialize in Brush Plating Repairs for varied industries Worldwide. Brush Plating repairs for mechanical components, saves on parts replacement and downtime.

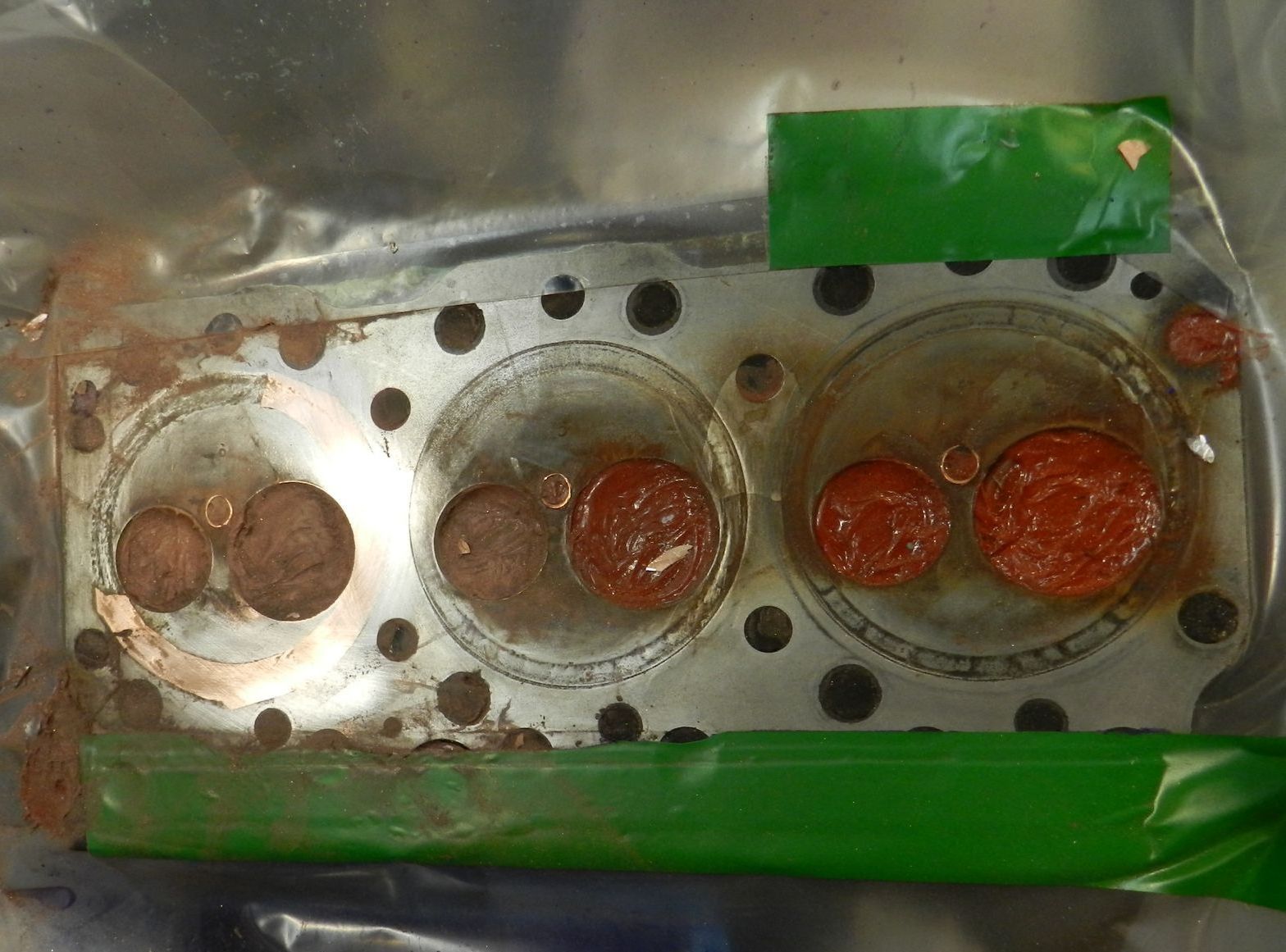

Brush Plating is exclusively used by Oil Tools Threading Industies Worldwide, for Accessories and Couplings

OUR TECHNOLOGY

Brush Electroplating &

How It Works

Brush Plating Process, facilitates localized metal deposition. Using a portable brush or applicator, a metal solution is transferred onto a substrate or component. Simultaneously, an electrical current prompts metal ions to bond with the substrate's surface, resulting in a thin and precisely deposited layer. This technique finds its application in repairs with Brush Plating and surface enhancements or treatments.

OUR KEY STATISTICS

Over 500 customers satisfied with their renewed components

Repair Jobs Completed

Oil & Gas Components Plated

Overseas Trainings Given

BRUSH PLATING ADVANTAGES

What Sets Us Apart?

Targeted Plating

Brush Plating is a portable and plating is PRECISE onto damaged areas.

Any SIZE and WEIGHT of a mechanical component for repair can be undertaken with Brush Plating.

Cost Effective

Brush Plating minimizes the neccesity of disessembly or replacement of the mechanical component.

Brush Plating saves valuable time and recources.

On-Site or In-situ Repair

Brush Plating is PORTABLE and repair can be performed on-site or in-situ.

You save on LOGISTICS and TRANSPORTATION costs.

Versatility

Brush Plating is versatile for any mechanical component requiring repairs.

Brush Plating provides value-added services for Oil Tools Anti-Galling applications